How China’s Automation Surge is Redefining Global Manufacturing

In 2024 installed 300,000 robots - more than the rest of the world’s installations combined (!!!) and nearly 10x the 34,000 robots installed in the US the same year!🤯

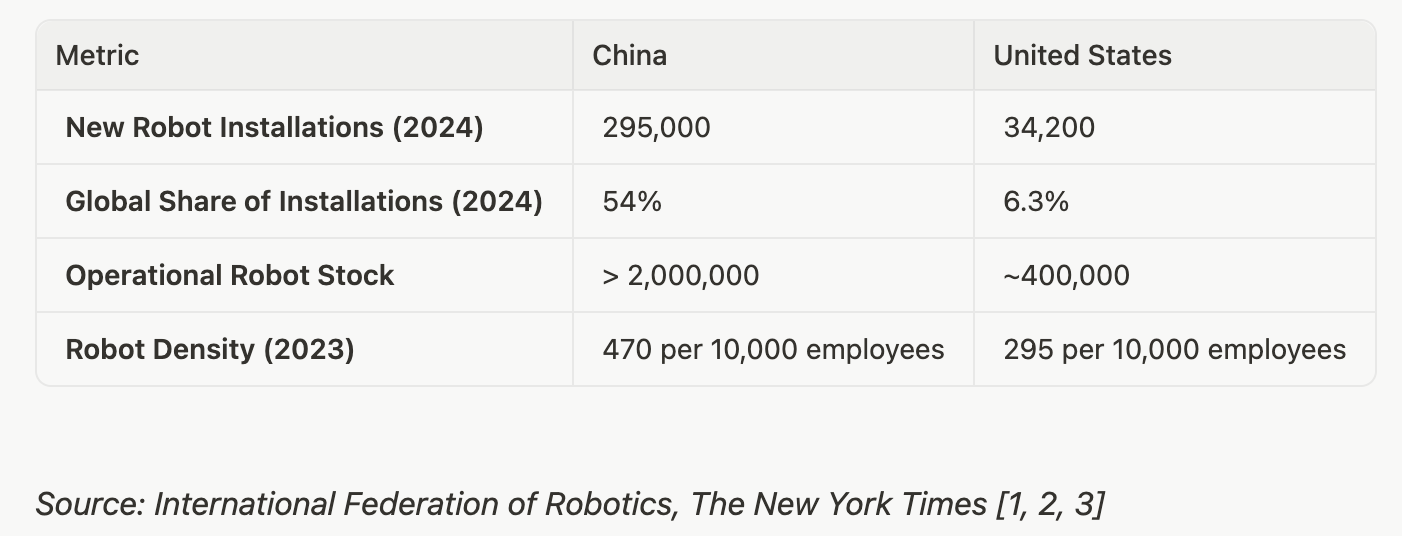

In 2024, a quiet revolution was taking place on factory floors across the globe, one that will fundamentally reshape the 21st-century economy. While the world was focused on AI headlines, China was busy installing an army of robots — nearly 300,000 new units in a single year. This figure is not just a testament to China’s manufacturing might; it is more than the rest of the world’s installations combined and nearly ten times the 34,000 robots installed in the United States during the same period.

This staggering disparity is more than just a statistic; it signals a tectonic shift in global manufacturing, with profound implications for trade, economic competitiveness, and national security... China’s automation drive, a core pillar of its long-term industrial strategy, is creating a new paradigm of manufacturing prowess that challenges the economic models of both developed and developing nations.

The Widening Automation Gap

The sheer scale of China’s robot adoption is breathtaking. According to the International Federation of Robotics (IFR), China’s operational stock of industrial robots has surpassed 2 million, a figure five times larger than that of the United States [2]. This rapid automation has propelled China to become the world’s third-most automated nation in terms of robot density, with 470 robots per 10,000 manufacturing employees, a figure that has more than doubled in just four years.

For the first time, Chinese manufacturers have sold more than foreign suppliers in their home country. Their domestic market share climbed to 57% last year, up from about 28% over the past decade. China’s operational robot stock exceeded the 2 million mark in 2024, the largest of any country.

This data paints a clear picture: while the United States is gradually adopting automation, China is pursuing it with an urgency and scale that is unmatched. This divergence is not a result of free-market forces alone but is a direct outcome of a deliberate and far-reaching national strategy.

Made in China 2025

To understand China’s meteoric rise in robotics, one must look to the “Made in China 2025” initiative. Launched in 2015, this state-led industrial master plan identified robotics as a critical sector for achieving technological self-sufficiency and global dominance in high-tech manufacturing. As the World Economic Forum notes, the plan was designed to “reduce reliance on foreign technology and move China up the global value chain” .

This strategy has been remarkably effective. A decade ago, China was heavily reliant on foreign robot manufacturers. Today, nearly 60% of the robots installed in China are domestically produced, a testament to the success of the government’s industrial policy [2]. This shift from importer to producer has not only created a massive domestic robotics industry but has also allowed China to drive down costs and customize automation solutions for its vast manufacturing ecosystem.

“The expectation for humanoid robots is to create another electric car industry. So from this perspective, it is a national strategy.” — He Liang, CEO of Yunmu Intelligent Manufacturing

More Than Just Machines: The AI-Powered Manufacturing Ecosystem

China’s advantage lies not just in the number of robots but in how they are integrated into a sophisticated, AI-powered manufacturing ecosystem. Chinese companies are leveraging artificial intelligence to monitor and optimize every aspect of factory performance, creating a system of continuous improvement that is difficult for competitors to replicate.

This fusion of AI and robotics is creating a new competitive landscape where efficiency, quality, and speed are paramount. As one supply chain consultant noted, companies in China “are using A.I. to swoop in and say which machines are doing great and which are a little off,” a practice that is not yet widespread in other parts of the world.

This advanced manufacturing capability provides a powerful buffer against economic pressures, including tariffs. By relentlessly driving down costs and improving quality through automation, Chinese factories can maintain their export competitiveness even in the face of trade barriers. This reality was highlighted in a New York Times report, which described China’s robot army as its “secret weapon in the trade war”.

Automation as a Strategic Asset

The implications of China’s robot dominance extend far beyond the factory floor. The concentration of advanced manufacturing capabilities in a single nation raises significant national security concerns for the rest of the world. Just as the world has become reliant on a few countries for oil or semiconductors, a similar dependency is emerging in the realm of robotics.

This technological supremacy has dual-use implications. The same technologies that power advanced manufacturing can be adapted for military purposes. The rapid development of low-cost humanoid robots by Chinese companies like Unitree Robotics, at a fraction of the cost of their Western counterparts, underscores the potential for these technologies to be deployed in a variety of contexts.

For the United States and other advanced economies, the challenge is clear. Competing in the 21st-century manufacturing landscape will require a renewed focus on automation and a national strategy to foster a domestic robotics ecosystem. As manufacturing becomes increasingly capital-intensive, the countries that lead in robotics will be the ones that lead in making things.

The Road Ahead: A New Era of Manufacturing

China’s surge in robotics is not a fleeting trend; it is the dawn of a new era in global manufacturing. The convergence of massive state-led investment, a vast domestic market, a growing pool of skilled technicians, and the integration of artificial intelligence has created a self-reinforcing cycle of innovation and dominance.

As China continues to push the boundaries of automation, the rest of the world faces a critical choice: either invest in the technologies and skills needed to compete in this new paradigm or risk being left behind. The robot revolution is here, and it is being led by China.

Check some more resources to dive deeper into the topic:

➡️International Federation of Robotics. (2025, September 25). Global Robot Demand in Factories Doubles Over 10 Years — Link.

➡️Tobin, M., & Bradsher, K. (2025, September 25). There Are More Robots Working in China Than the Rest of the World Combined. The New York Times — Link.

➡️International Federation of Robotics. (2024, November 20). Global Robot Density in Factories Doubled in Seven Years — Link.

➡️World Economic Forum. (2025, June 26). Made in China 2.0: The future of global manufacturing? Link.

➡️Bradsher, K. (2025, April 23). China Has an Army of Robots on Its Side in the Tariff War. The New York Times — Link.

🤝 Passionate about HardTech?

Have comments, want to share some thoughts or ask about sponsorships? Send me a note: https://bit.ly/3SXPifd

You can also find me on LinkedIn and Substack 🛠️

If you are interested in AI, Robotics & HardTech, check my previous posts:

➡️The Physical AI Revolution: Mapping the $60 Trillion Transformation

❗️The VC Industry Loves Data. But Doesn’t Use It…

— Is it why it’s ‘dying’?

➡️19 Robotic Hands Startups to Watch

➡️ The world doesn’t fix itself. These startups are trying /Top 100 HardTech Startups

➡️ Will we have a chatGPT moment for Robots?

➡️ The Coming Scarcity of Humanity

➡️ The Art and Science of Venture Capital Investing

➡️ Deep Thinkers & Builders in Tech, Science and Bio

➡️ Humanoids Don’t Exist in Isolation / It Takes an Ecosystem to Bring Them to Life!

➡️ Clone Alpha: The Next Leap in Humanoid Robotics

➡️ ‘Made in China’-Robotics Market Overview

➡️ The Science of Networks: From Theory to New Realities

#AI #Robotics #HardTechReads #Startups #DeepTech #Automation